Cloth

Cabinet

This I would do over if I had more room. It works fine but

since the bulk of the material is cut on the diagonal it would

work better if you have about 6 feet of table to pull the

cloth out on. Keep the top at 36" high to match the

bench. If you somehow have the room, allow 24" between

the cutting bench and the workbench but in such a way as you

can put in a filler piece to bridge the two tops and do longer

cuts. Yah Chrissi, dream on. Just make sure it can close up

nice and dust tight.

Make sure on the tabletop you put guide lines for alignment

and cutting at 45o

etc.

We also ended up making a covered roller holder for large

rolls of peel ply above the cutting top. This stuff comes on

60" wide rolls so it would be a pain to put into the

cloth cabinet.

The

discussion of what tool is best to cut the different glass,

kevlar, carbon and peel ply materials with comes up on a

regular basis. We can safely say we tried them all (plans

scissors, rotary wheel pizza cutter) and gave each a fair

chance to prove itself but nothing came remotely close to the

joy we get from the Dritz electric scissors.

Electric

piranhas!

Dritz electric scissors will cut through multiple layers of

wet glass, if you go clockwise around a part with the upper

scissor blade on top of the part you can wet trim with nearly

zero overhang; no need to wait for just the right moment

to knife trim.

Wicks

aircraft carries them as well as the spare cutter heads which

are cheap. You can probably build the whole plane with one

spare.

Wicks

aircraft carries them as well as the spare cutter heads which

are cheap. You can probably build the whole plane with one

spare.

We wrap them up in saran and then cover them in masking tape,

then slit around the battery pack with a razor and cover the

joint with a single wrap of tape. Clean up just the tips with

a bit of acetone. The cutting edges have carbide inserts for

long durability. They hold a charge for quite awhile and also

come with a cheater cord in case you forget to charge them.

Cutting BID on the

bias

Awhile ago someone

asked us about this and I realized back when we first started

how we spent an inordinate amount of time fussing with BID

getting it set up and cut.

Every piece of BID you are going to use will be cut on the

bias; setting the weave 45 deg with respect to the orthogonal

axis of the part.

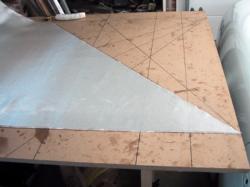

First

thing we did was set up the cutting table with some guide

lines like shown here at the right, click image for a larger

picture.

There

are side lines for the cloth width to lay it straight and at

the end of the table lines at 30, 45, 60 degrees on both

sides. Make these dark with a medium Sharpie and you will be

able to see them through the cloth.

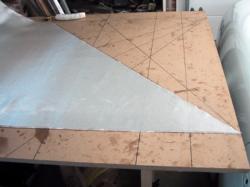

Next the BID cloth

is pulled by both corners straight out till it reaches the end

of the table. In the picture shown below it has already been

aligned and cut on the 45 degree bias, click the image to see

how the bias lines are clearly seen in the cloth.

Rather then fuss too much trying to straighten the cloth out,

make the first cut following the bias line of the cloth, then

adjust the cloth straight down the sideline and then adjust

the bias cut portion to the 45 degree line, now your cloth is

straight. Depending on whether your cloth is on an original

mill roll or cut to length and re-rolled by a supplier the

bias lines could be from left to right or the reverse.

Measuring

width of cut is perpendicular to the bias cut line, either

make a small mark at the edge or a snip with you new Dritz

scissors, then run them straight up the bias line of the

weave, it will become obvious when you do it the first time.

No fuss, no straightedge, no marking lines.

Measuring

width of cut is perpendicular to the bias cut line, either

make a small mark at the edge or a snip with you new Dritz

scissors, then run them straight up the bias line of the

weave, it will become obvious when you do it the first time.

No fuss, no straightedge, no marking lines.

That's

pretty much all there is to it unless you are cutting out a

specific shape otherwise most of the time you keep the roll

trimmed on the bias line.

Straight

cuts of UNI we cut 1/2" wider, then peel out 1/4" of

strands on each side to give it a selvage edge. This prevents

loose strands from gumming everything up later.

Wicks

aircraft carries them as well as the spare cutter heads which

are cheap. You can probably build the whole plane with one

spare.

Wicks

aircraft carries them as well as the spare cutter heads which

are cheap. You can probably build the whole plane with one

spare.

Measuring

width of cut is perpendicular to the bias cut line, either

make a small mark at the edge or a snip with you new Dritz

scissors, then run them straight up the bias line of the

weave, it will become obvious when you do it the first time.

No fuss, no straightedge, no marking lines.

Measuring

width of cut is perpendicular to the bias cut line, either

make a small mark at the edge or a snip with you new Dritz

scissors, then run them straight up the bias line of the

weave, it will become obvious when you do it the first time.

No fuss, no straightedge, no marking lines.