Our Rotary Engine FAQ

Lycoming recently published a statement proudly proclaiming they were finally able to say they were manufacturing to "automotive standards"… that scared the hell out of me!

Please Note: It

is not our intention to trash certified aircraft engines. It is our

understanding they are managing to

do that without our help:

Certified

Aircraft Engines Bloops, Blunders & Recalls by David Leonard

It has been said that if the rotary engine had arrived in Detroit first, someone proposing a reciprocating piston engine would have been laughed out of town.

Lets pause first

to an alternative reality:

Put yourself in this frame of

mind; you have a highly efficient horsepower to weight ratio engine with 3

primary moving parts, one is a robust part with massive bearing surfaces that

just rotates, the other two follow a gentle eccentric path. There are no small

parts, mechanisms or driven parts that handle sensitive timing issues of

mechanical parts. In one minute of cruise operation the eccentric shaft just

rotates 6000 times and the two rotors rotate 2000 times (thanks Neil for

correcting me =). Each of the two rotors

has one power cycle per revolution of the eccentric shaft. That is all that

happens.

Along comes a bright kid with a new engine. It weighs about the same,

produces a little less power, burns the same amount of fuel. You are curious. It

is explained that like your rotary engine it has 4 cycles and also like your

rotary it has two power pulses per revolution of the crankshaft. But his

crankshaft only rotates at half the speed of yours so in one minute it has only

half as many power cycles... BIG ones. He goes on to explain the reciprocating engine theory,

and how all the little valve train components work like a symphony.

All in all

you are trying to hold in your head how 26 primary moving parts, some moving or

rotating at nearly 3000 cycles per minute and some at 1500 cycles per minute, accelerating,

decelerating, stopping, reversing direction and accelerating again. All the time

trying to keep these parts cool and lubricated... oh, did he mention the precision

fits and adjustments of all those parts? Think of all the opportunities for

quality control to screw up.

By now you are marveling at the ingenuity and perseverance of this kid but at the same time

feeling pity because in order to reinvent the wheel he has come up with a Rube

Goldberg contraption called a reciprocating engine. What would you do? Would you trust it with your

life?

Granted there are many of these reciprocating engines out there now and they are

the accepted norm. No denying that. They also have a "proven" track

record of sorts. You cannot look to the NTSB or anywhere else for data but this

is for certain, the probability of breaking a crankshaft, sticking a valve,

having a valve head break off or my favorite... blowing a whole cylinder off,

the probability of one or more of these things happening to you is far greater

than you ever winning the lottery.

Probably the first words out of the mouth of people who have little knowledge of the modern rotary engine are something about "the seals". True, early versions had seal problems. This is an issue from early in the engine’s history that has long since been resolved.

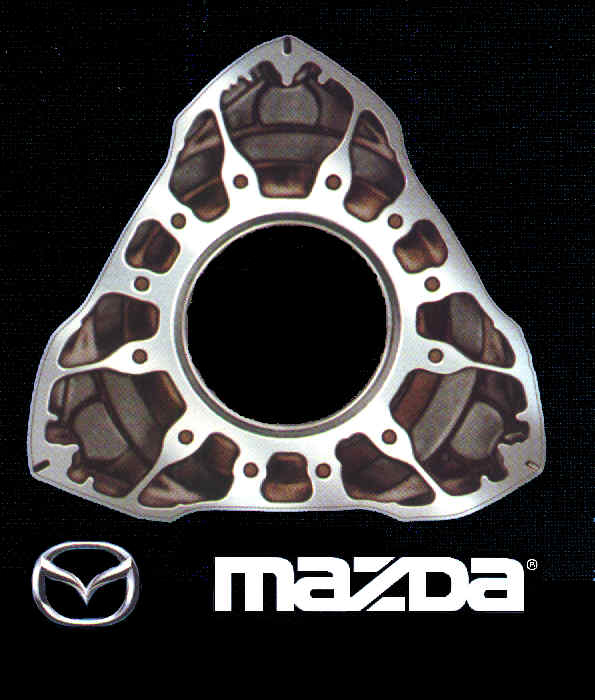

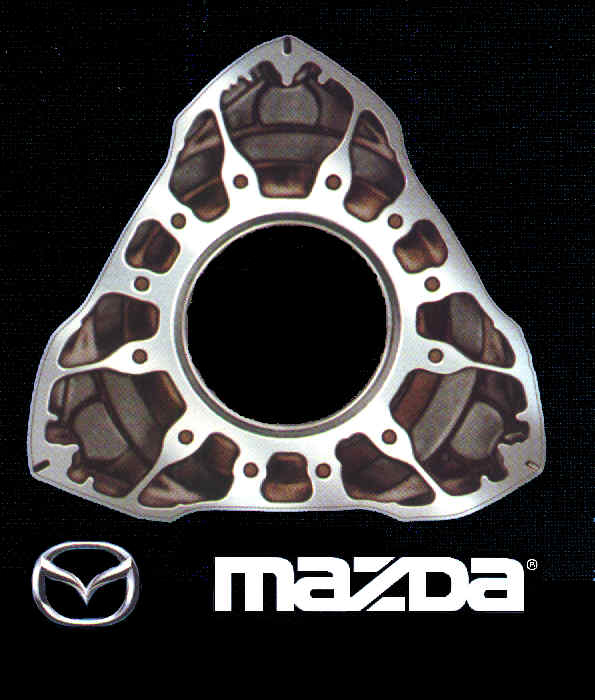

|

Intake ports |

|

Two spark plugs per rotor |

|

Exhaust ports |

Image from Real World Solutions, Inc. |

WEB SITE ROTARY ENGINE ILLUSTRATED

3 moving parts (not including oil pump and “distributor”) produce all the power

rotors rotate at ˝ shaft speed

There is no "crank" shaft; the driving shaft has two eccentric lobes, think of each of these functioning more like a single pinion planetary drive.

Each triangular rotor has three combustion chambers on it.

There are already two spark plugs per cylinder (inexpensive automotive plugs).

30% of the engine cooling comes from the oil cooling. The rotors are hollow and bathed in a cooling oil spray from the rotating eccentric shaft.

Because part of the cooling comes from the oil cooling, the water radiators are smaller.

Two fuel injectors per rotor.

The Real World Solutions engine computer handles the fuel injection and ignition via two redundant computers.

This is a true aviation/automotive dual fuel engine because it does not use an exhaust gas oxygen sensor for engine control. Leaded fuel disables these sensors and causes malfunctions in other systems.

STRENGTH / POWER / DURABILITY

The rotary engine is built in a stack or sandwich; a front plate, a rotor housing “cylinder” with rotor inside, another plate between rotor housings, another rotor housing, a back plate, and finally the eccentric shaft through the whole thing. This stack of plates and housings is all held together by some big long bolts. It looks like your Lycoming or Continental with the cylinders all cut off, about that size too.

The engine is basically the same from it’s earliest model, just refined.

The two rotor engine is capable of 450 HP in racing trim.

The three rotor engine is capable of 900 HP in racing trim.

The 690 hp four rotor engine that won the 1994 LeMans 24 hr race was based on the same engine block, rotors and eccentric shaft components as the two and three rotor engines. In the case of the three and four rotor engines the eccentric shaft even has joints in it and the cross section is the same for all. Breaking or damaging a shaft is unheard of even in hard racing use.

The Real World Solutions “ReDrive” (Reduction Drive or PSRU) is based on the Ford truck six pinon reduction in their HD automatic transmission.

DURABILITY

Ceramic tip seals

Silicone encapsulated Teflon O-ring seals

Bearings do not wear because unlike a reciprocating engine, any blow by from one combustion chamber is most likely to go into an adjacent combustion chamber and eventually out the exhaust. The oil does not become contaminated with carbon or ingested airborne particles.

The automotive engine used a small amount of the crankcase oil and injected it into the combustion chambers for seal lubrication, the pickup point is diverted to a separate tank of 2-stroke oil more suitable for combustion chamber lubrication. Alternatively you can use some premix in your fuel tanks.

COSTS

To be realistic, initial installation

cost is probably on par with a used aircraft engine installation. What you save

in having a new rotary engine built you spend on mounts, coolers, plumbing,

drive system, and engine controller. If you are trying to save money or time

building your plane this is not the way to go.

But, once you are in the air you will then save gobs of money.

Inexpensive to build. A two rotor engine can cost anywhere between $3500 to $5000 depending on parts used and the person who does the work.

Inexpensive to rebuild. We were told the parts to tear down and rebuild the engine for an inspection are about $250, provided no major components require replacement.

Inexpensive to maintain. Other than frequent oil (Mobil One), oil filter, fuel filter changes, inexpensive automotive spark plugs, there is nothing to check, adjust or service.

For the price of an aircraft engine overhaul, you can have a new rotary engine built to your specifications from all new parts but that should not be necessary.

MODIFICATIONS

Porting

Oil injection bypass

Water jacket turbulators

Seals

Oil pan options

MOUNTING

COOLING

FUEL INJECTION

INTAKE

TURBOCHARGING

MORE INFORMATION

We

strongly recommend anyone considering a Mazda rotary engine for their plane talk

to as many people building and flying these as possible.

It is a different animal and as of yet there are no "firewall forward

solutions" out there. There may never be a universal solution for this or

any other engine but the popularity of this engine is growing rapidly. The Var's

RV series of aircraft may well be the first to see a turnkey solution for 3rd

party vendors. In the case of canard aircraft such as our Cozy MK-IV, the

solutions are somewhat different due to the pusher configuration. It is through

the efforts of individuals and collectively on lists like the Fly

Rotary news list where people put their heads together to solve

problems and create solutions.

Components

Engines

ReDrive (Reduction Drive, PSRU (Propellor Speed Reduction Unit))

FADEC (Fully Automated Digital Electronic Control)

Turbo Charger Exhaust Manifolds

TurboChargers

Radiators

Engine Mount Bushings

More Information

ACRE

Builders & Flyers

Canards:

Greg Richter

John Slade

Bulent Aliev

Randi & Chrissi

Other Aircraft: